Shepard was built with the goal of providing safe, reliable electricity to Albertans long into the future, with a simultaneous commitment to reducing emissions and using resources responsibly.

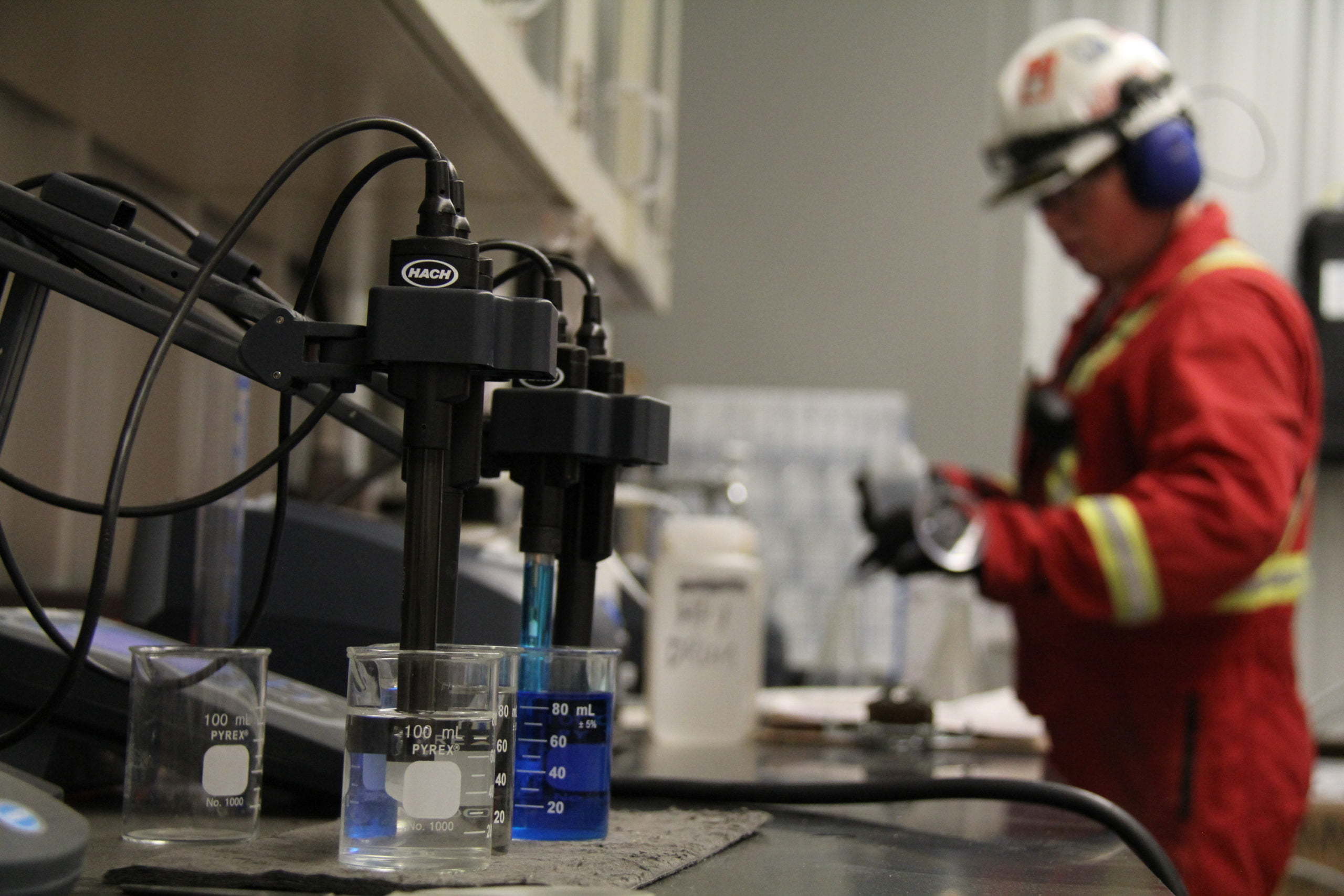

By design, Shepard uses reclaimed wastewater from The City of Calgary’s Bonnybrook Wastewater Treatment Facility for all its power generation needs – a first in Alberta. This design feature prevents from having to draw nearly 6 million cubic meters of fresh water from the Bow River every year. Most of the intake water is used in the large cooling tower array, while the remainder is purified in the on-site water treatment plant to be used for boiler water make-up.

Using reclaimed water presents many challenges. From a chemistry perspective, reclaimed water is far more variable than fresh water and contains a large proportion of inorganic and organic compounds. Some of the substances can cause equipment damage.

For example, water hardness can cause impurities in water to form solids on machinery, the same way it does in a kettle. Other substances must be kept within strict concentration limits for health and environmental reasons. For some substances, the analytical test methods themselves were found to be influenced by the unique water chemistry, and new sample preservation methods had to be developed.

When water is used in a power generating plant, the quality generally declines with use. This is especially so in the cooling water cycle where every pass through the cooling towers increases the concentration of dissolved substances.

After nearly three years of meticulous research, observation and lab testing, the team at Shepard was able to pinpoint the optimal operating efficiency of the cooling towers while still maintaining all cooling water chemistry parameters within their required concentration limits. This perfect balance has reduced the plant’s annual wastewater volume by 25-30 per cent – saving nearly 500 million litres per year with a related annual cost savings of more than $1.5 million. Now into the third year of the optimization initiative, the process has been continuously improving. As of the third quarter of 2020, Shepard has already saved $1.7 million while still increasing the megawatt output being produced.

As freshwater resources become increasingly scarce in our world, industrial users will need to turn to reclaimed water to meet their process requirements. The research work that Shepard is conducting towards better understanding and using reclaimed water is thus not only important today but will become increasingly important for future generations.

Now into the third year of the optimization initiative, the process has been continuously improving. As of the third quarter of 2020, Shepard has already saved $1.7 million while still increasing the megawatt output being produced.